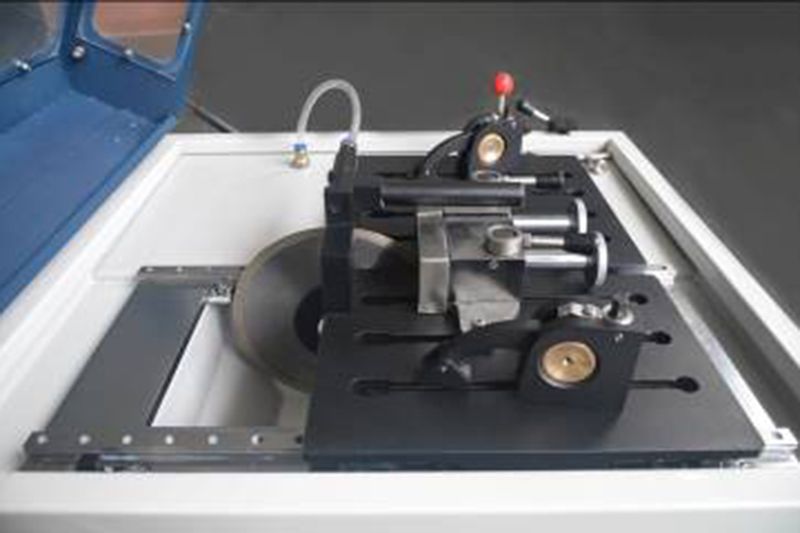

QG-PCB30 Precision Cutter, Automatic & Manual

Metallographic Precision Cutting Machine

- Cut-off wheel:Φ180×1×Φ22mm

- Max. cutting capacity:Φ 30mm

- Motor: DC brushless, 1.2 kW

- Cutting method: Automatic/Manual, Spindle feeding or table feeding

Request a quote

Designed for versatility and efficiency, this automatic precision cutting machine excels in various cutting applications, including PCB plates, metal materials up to ⌀30mm, electronic components, and embedded samples. Despite its compact size, it offers powerful performance.

Features

- QG-PCB30 precision cutter adopts a speed adjustable motor to drive the cut-off wheel for cutting and it allows for manual and automatic operation. Based on the sample material and personal habits, the cutting can be controlled by hand-operated wheel or by cutting table propulsion. Automatic cutting mode is also available based on set parameters.

- Exquisite overall design: built-in stainless stell circulating filter cooling water tank adopts 80% water and 20% cutting fluid for lubricating the cutting blade and sample. This effectively prevents the sample surface from heat burn, and protects the rail and ball screw form rusting.

- The machine automatically stops when opening the cover. This safty protection enables the working area being enclosed. The transparent cover is for observation.

- The cutting table is available for different clamp tools and the clamp device can be disassembled for cleaning, improving the machine practicality.

- The cutting table, clamp jaws, and inner tank are all made of stainless steel, ensuring long-lasting durability and easy maintenance.

Cutting samples

Technical Data

| Model | QG-PCB30 |

| Cutting Method | Manual / automatic, spindle feeding or table feeding |

| Feeding Speed | Manual / automatic 1-36mm/min (adjusting step 0.1mm/min) |

| Cut-off Wheel | ⌀180×1×⌀22mm |

| Max. Cutting Capacity | ⌀30mm |

| Max. Travel | Spindle travel 140mm Table travel 230mm |

| Spindle Speed | 500-3000r/min |

| Electromotor Power | 1.2kW |

| Cutting Table | 245×415mm, T-slot 8mm |

| Clamping Tool | Quick clamp (jaw height 45mm) Vertical clamp (opening 60mm) |

| Control and Display | 7 inch touch screen |

| Power Supply | 220V, 50Hz, 8A |

| Dimensions | 620×740×380mm |

| Net Weight | 80kg |

| Water Tank Capacity | 36L |

| Pump Flow | 12L/min |

| Water Tank Dimensions | 300×500×450mm |

| Water Tank Weight | 20kg |

Get in Touch

SCTMC is a reliable manufacturer of metallographic sample preparation equipment and hardness testers. Our factory is equipped with more than 50 sets of CNC lathes, Mazak machine tool from Japan, German Zeiss CMM and other advanced machines for manufacturing and inspecting, enabling us to provide high quality equipment which is highly praised by 150+ dealers and 1500+ clients across countries at home and abroad. Our machines have found wide applications in the automotive industry, metallurgy, R&D, universities and testing labs for material preparation, testing and analysis of all types of materials, such as metals, ceramics, rocks and minerals, organic materials and plastics. Our products deliver the highest quality, innovation, accuracy, efficiency, operator safety and repeatability you need.