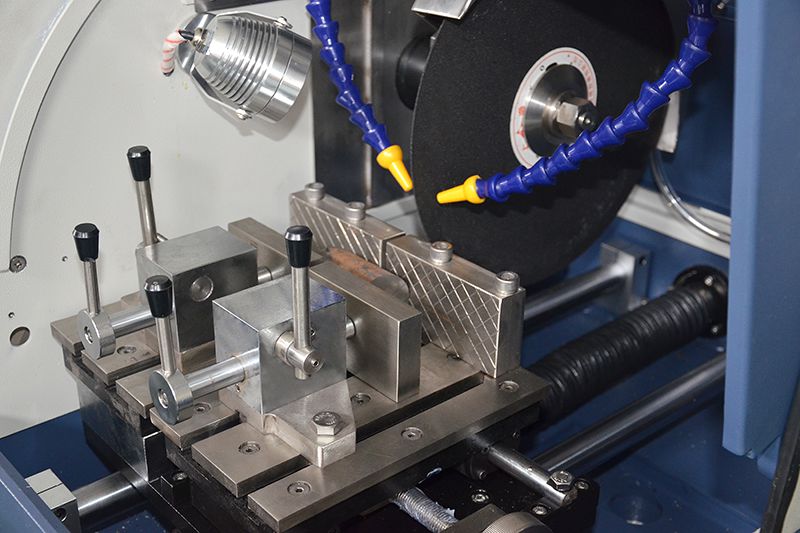

QGZ-65 Metalloraphic Abrasive Cutter, Automatic

Abrasive Cut-off Machine

- Cut-off wheel: Φ300×2×Φ32mm

- Max. cutting capacity: Φ65mm

- Motor: variable frequency, 2 kW

- Cutting method: Automatic, Table feeding along Y axis

Request a quote

Features

- QGZ-65 automatic metalloraphic abrasive cutter adopts electromechanical separation structure to effectively protect electrical safety. It features flexible cutting mode and convenient maintenance.

- Machine body is made by thick sheet metal, which is firm and stable.

- Intelligent feeding: the speed can be automatically adjusted according to the sample hardness to avoid blockage. The Y axix can be automatically and accurately controlled, and it will return automatically after cutting. This cut-off machine is suitable for cutting materials of various shapes and sizes and the cut surface is bright and flat without burns.

- Z axix can be adjusted manually for different sizes of cutting wheels and it can automatically compensate the loss during cutting, effectively improving the utilization of the cutting wheel.

- 7 inch high definition color touch screen offers intuitive display and easy operation.

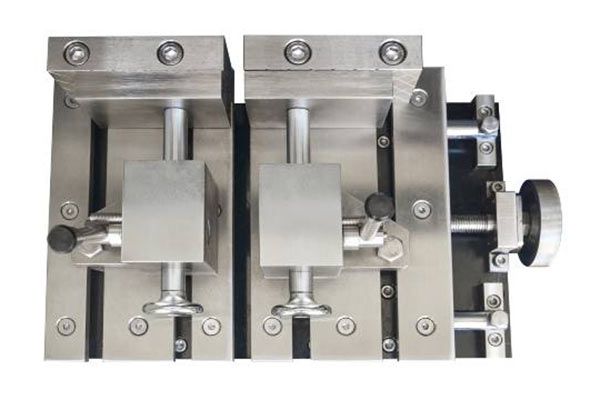

- Double-sided quick clamp and T-slotted table come with fast operation, corrosion proof and easy replacement.

- Mobile circulating cooling water tank has three adjustable cooling water channels to prevent the samples from burn damge. The water guns are easy to be cleaned independently.

- The machine automatically stops when opening the cover. This safty protection enables the working area being enclosed. The transparent cover and LED lamp are for ease of observation.

Technical Data

- Cutting mode: continuous cutting, pulse cutting

- Feeding speed: manual/automatic, 1~240mm/min (max. speed is at zero load)

- Y axis travel: 235mm

- Z axis travel: 35mm

- Spindle speed: 500~3000r/min

- Cutting table: 350×220mm with 12mm T slot

- Clamp tool: quick clamp, jaw height 60mm

- Display and control: 7 inch touch screen

- Dimensions: 800×760×1370mm

- Net weight: 280kg

- Water tank capacity: 60L

- Pump flow: 25L/min

- Water tank size: 565×360×600mm

- Water tank weight: 27kg

Accessories

Get in Touch

SCTMC is a reliable manufacturer of metallographic sample preparation equipment and hardness testers. Our factory is equipped with more than 50 sets of CNC lathes, Mazak machine tool from Japan, German Zeiss CMM and other advanced machines for manufacturing and inspecting, enabling us to provide high quality equipment which is highly praised by 150+ dealers and 1500+ clients across countries at home and abroad. Our machines have found wide applications in the automotive industry, metallurgy, R&D, universities and testing labs for material preparation, testing and analysis of all types of materials, such as metals, ceramics, rocks and minerals, organic materials and plastics. Our products deliver the highest quality, innovation, accuracy, efficiency, operator safety and repeatability you need.