Shanghai Shangcai Testermachine Co., Ltd. (SCTMC) is a manufacturer of metallographic testing equipment, providing a complete range of materialographic solutions, products, and services, tailored for your individual lab process, which deliver the accuracy, efficiency, and repeatability you need – every time. Our sectioning, mounting, grinding and polishing, and hardness testing metallographic equipment along with consumables are used by metallurgical, research & development, quality control departments and failure analysis facilities. SCTMC is located in Lin-gang Special Area of China (Shanghai) Pilot Free Trade Zone, enjoying the geographical advantages of Yangze River Delta Economic Zone.

Founded in 2005, our company has a R&D team with over ten years of experience, a professional consultant team, independent design capacity and many equipment core technology patents. Besides, SCTMC owns advanced machining workshops, which are equipped with more than 50 sets of CNC lathes, Mazak machine tool from Japan, German Zeiss CMM and other advanced machines for manufacturing and inspecting. We also have been making continuous innovation and progress in processing technology and material selection to ensure the product of high precision. Quality and time are controlled in our hands, with abundant technical force and guaranteed after-sales service. Our complete portfolio of genuine consumables and state-of-the-art equipment, backed by our solid global supply chain, mean you always get the best possible lab results, and maximum return for your investments.

- SCTMC is a member of metallurgical branch and mechanics branch of National Technical Committee of Standardization of Steel.

- SCTMC is one of the drafting committees of National Standards of Rockwell, Brinell and Vickers harness testers. Draft standard numbers: GB/T230.1-2018, GB/T231.1-2018, GB/T230.2-2012, GB/T231.2-2012, GBT4340.2-2012.

- Our company has a R&D team with over ten years of experience, a professional consultant team, independent design capacity and 55 patents of equipment core technology.

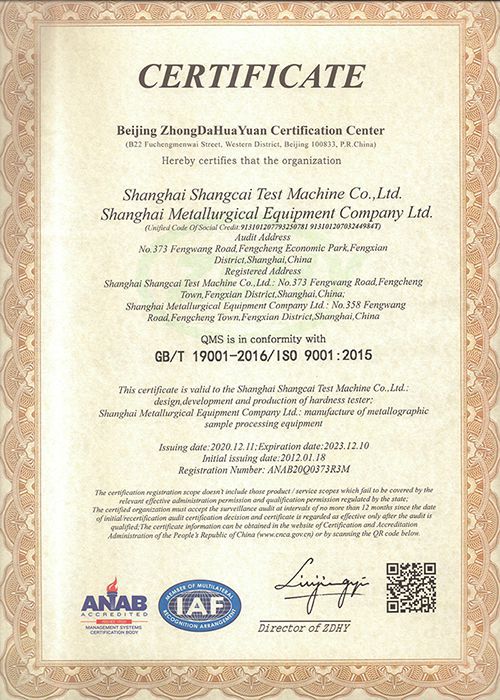

- SCTMC has the European Union CE, ISO9001-2015 and other safety and quality management system certifications.

- SCTMC owns 20 years of professional manufacture experience, 150+ estmeed partners and over 1500 high-quality client base.

- All the products are completely researched and developed, produced by ourselves, featuring complete varieties, and the high-end automative equipment is among domestic leading level.

- SCTMC has established long-term cooperation with various steel research institutes, universities, aerospace, automotive, metallurgy, manufacturing and other industries.

SCTMC owns unequalled manufacturing capacity, over 80 professional technicians and more than 50 sets of CNC machine tools, capable of producing over 3000 machines.

We have been adhered to lean production management for many years, ensuring stable equipment quality and fast delivery cycle. Various personalized customization demands are available.

SCTMC owns a complete machining worshop, covering full ranges of processing equipment like machining center, CNC lathe, milling machine, grinding machine, drilling machine, planing machine, etc. Therefore, all the key components are produced by ourself to ensure the machining quality and delivery cycle.

SCTMC is equipped with German Zeiss CMM, high precision imager and Rockwell hardness tester for the inspection of core components like the flatness of the grinding disc, the roundness of the mounting mold, the coaxiality of the lead screw and the hardness of heat treated material. This ensures the accuracy and performance of the components.