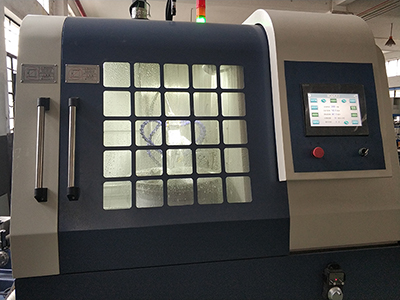

SCTMC is professional leader in materials testing equipment and solutions since 2005. Today we continue to partner with leading manufacturers and research centers that are at the cutting edge of materials testing: automotive industry, metallurgy industry, aerospace material industry, education and R&D, manufacturing industry, testing services & labs to name a few. Let us know how we can assure your quality in metallographic sample preparation through our expert process review and we can provide the best solutions to your application demands with our full range of metallographic equipment and hardness testers.

SCTMC has been focused on the manufacture of metallographic sample preparation equipment and hardness testers for the automotive industry. We can provide reliable testing equipment, deep expertise and timely service to material scientists, researchers and technicians. Our metallographic machines are widely used in various automotive applications, including:

-

Suspension components

Suspension components -

Steering rack

Steering rack -

Section sparkplug

Section sparkplug -

Gear hardness testing

Gear hardness testing -

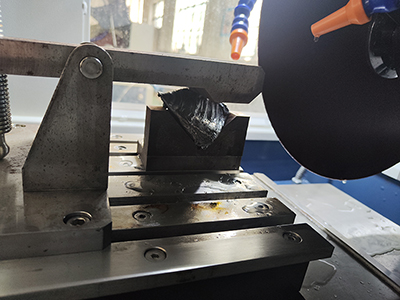

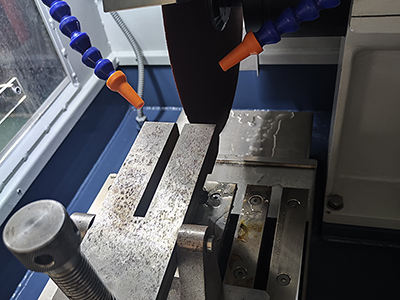

Automotive lithium battery sectioning

Automotive lithium battery sectioning -

Section CV joint

Section CV joint

SCTMC develops and delivers metallography equipment and consumables for sample preparation used in metallurgical industry for mass production of steel and other metal products, including structural parts like constructions and bridge, ball bearing, etc.

- Casting & forgings testing

- Welded components testing

- Aluminum sheet/coil

- Titanium components

- Ceramics

Aerospace industry relies on material testing and metallographic support. SCTMC has become a trusted partner of Chinese aerospace companies due to our reliable equipment and highly skilled service team. Our materials testing and metallographic equipment has been proven to satisfy the strict requirement and is ideal for the following applications:

- Turbine blades

- Fasteners (screw/nut)

- Aircrafe structure

- Sample preparation of plasma spray

Universities and research institutes around the world rely on metallographic sample preparation equipment and testing equipment for various precise material microstructure analyses. Analyzing the structure and property of materials is critical to many industries and applications. No matter you are learning metallography theory or participating in the research, SCTMC provides reliable and durable metallographic equipment to assist in your research, including cutting, mounting, grinding, polishing and hardness testing.

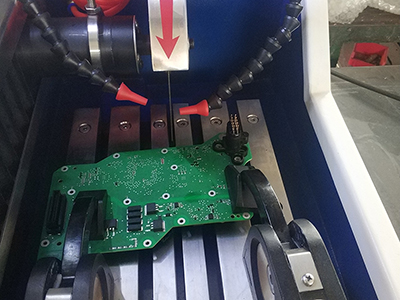

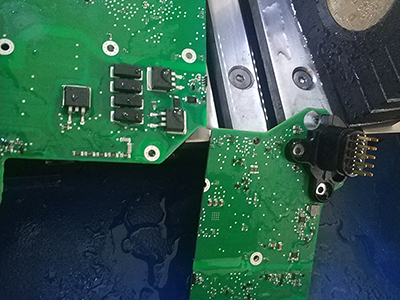

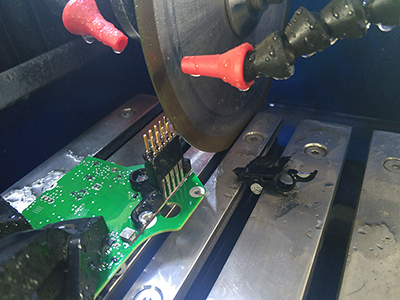

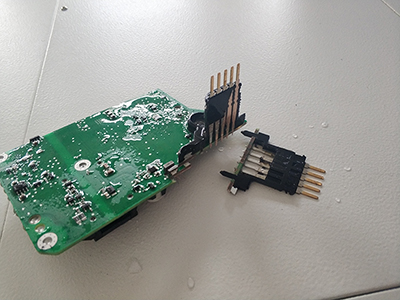

The electronics industry is dedicated to the production of electronic devices, components, and specialized materials. This sector includes the manufacturing of computers, televisions, radios, communication devices, radar systems, and electronic instruments. It also produces essential components like resistors, capacitors, inductors, printed circuit boards, connectors, and vacuum tubes, along with high-frequency magnetic materials, high-frequency insulating materials, and semiconductor materials. Ensuring proper soldering of circuit boards and components is vital for product performance. Our high-quality sample preparation equipment supports detailed research and testing, ensuring your projects proceed smoothly and efficiently.

Bearings are critical components in modern machinery, playing a key role in supporting rotating parts, reducing friction during movement, and maintaining precision. The development and research of bearings require precise sample preparation to ensure high performance and reliability. Our advanced sample preparation equipment provides the necessary support for bearing research, helping you achieve consistent and reliable results. Whether you are working with quenched, tempered, annealed, or other types of materials, our tools help ensure successful outcomes in your studies.