560RSSZ Digital Rockwell Hardness Tester, Automatic Type

Hardness Testing Machine

- Test force range: 3kgf (29.42N) ~ 150kgf (1471N)

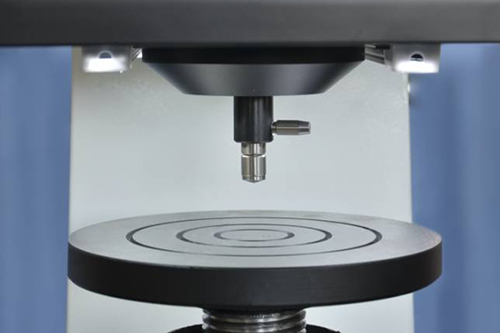

- 560RSSZ Digital Rockwell hardness tester adopts electric loading and unloading of test force, eliminating the use of weight. It supports for testing of Rockwell and superficial Rockwell scales.

- It supports conversion scales of different kinds of hardness.

- This hardness tester features arc correction function.

- Touch screen is equipped for display and operation, capable of displaying dynamic curve and real-time monitioring of the working status of force sensor and displacement sensor.

- One-button operation allows automatic performing of the rising of specimen, the loading, dwelling and unloading of the indenter, displaying of the hardness, and homing of the test table.

Request a quote

- This hardness tester features data storage function, automatic calculation of maximum, minimum and average vaule.

- The test results can be printed for output and a RS232 port is designed for connecting to the computer for output.

- The main body is made from cast aluminum, achieving 99% rigidity and minimizing deformation

- The device integrates a high-precision gravity sensing system with a zero-gap ball screw, ensuring a 1:1 force control ratio for precise and consistent loading every time

- Equipped with a force sensor from a renowned American brand, offering a repeatability of ±0.05%

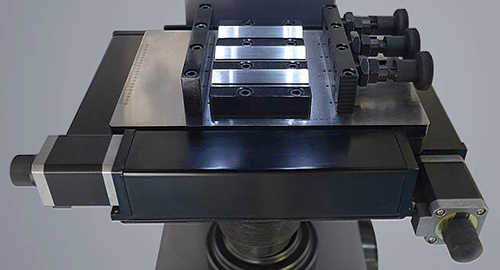

- Features a screw rod combined with NSK bearings from Japan. After heat treatment, the screw rod achieves a hardness of 35-40HRC, ensuring stable test data across different heights

Applications

560RSSZ Digital Rockwell hardness tester is suitable for the testing on hard alloy steel, aluminum alloy, copper alloy, bearing alloy, galvanized, chrome and tin coated materials.

Technical Data

- Pre-load test force: 3kgf (29.42N), 10kgf (98.07N)

- Total test force: 15kgf (147.1N), 30kgf (294.2N), 45kgf (441.3N), 60kgf (588.4N), 100kgf (980.7N), 150kgf (1471N)

- Max. sample height: 310mm

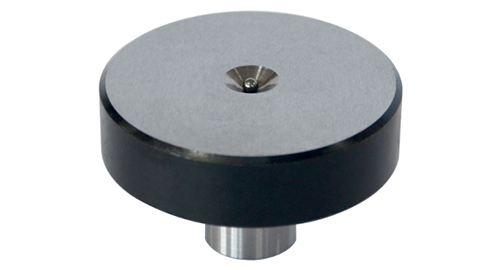

- Indenter: diamond Rockwell indenter, 1.588mm tungsten carbide ball indenter

- Loading method: automatic (loading/dwell/unloading)

- Hardness reading: LCD touch screen

- Test scale: HRA, HRD, HRC, HRFW, HRBW, HRGW, HRHW, HREW, HRKW, HRL, HRM, HRP, HRR, HRS, HRV, HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y, HR30Y, HR45Y

- Conversion scale: HV, HK, HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRKW, HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW, HBS, HBW, HSD, HLD

- Hardness resolution 0.1HR

- Dwell time: 0~99s

- Throat depth: 150mm

- Execute standard: ISO 6508, ASTM E18, JIS Z2245, GB/T 230.2

- Dimension: 535×280×890mm

- Net Weight: 80kg

Optional Accessories

Get in Touch

SCTMC is a reliable manufacturer of metallographic sample preparation equipment and hardness testers. Our factory is equipped with more than 50 sets of CNC lathes, Mazak machine tool from Japan, German Zeiss CMM and other advanced machines for manufacturing and inspecting, enabling us to provide high quality equipment which is highly praised by 150+ dealers and 1500+ clients across countries at home and abroad. Our machines have found wide applications in the automotive industry, metallurgy, R&D, universities and testing labs for material preparation, testing and analysis of all types of materials, such as metals, ceramics, rocks and minerals, organic materials and plastics. Our products deliver the highest quality, innovation, accuracy, efficiency, operator safety and repeatability you need.