XHBT-3000Z III Digital Brinell Hardness Tester with 3 Indenters, Automatic Type

Hardness Testing Machine

- Test force range: 62.5kgf (612.9N) ~ 3000kgf (29420N)

- XHBT-3000Z III Digital Brinell hardness tester comes with 10 level of test force and 13 Brinell hardness test scales, making it suitable for testing various metal and non-metal materials.

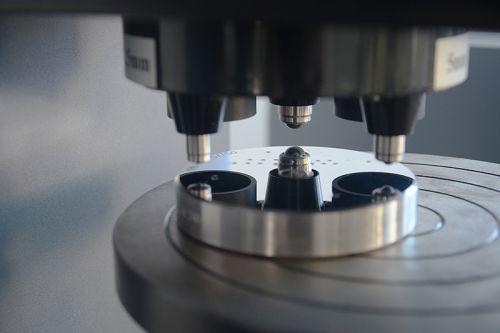

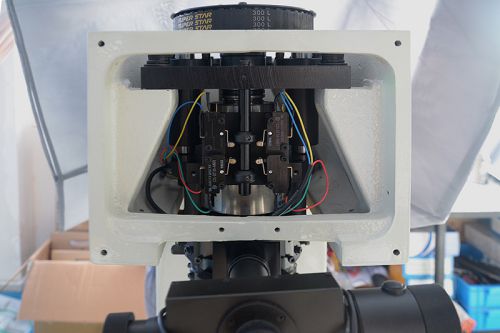

- With three indenters and two objectives, this hardness tester is capable of testing different samples with no need to change the indenters.

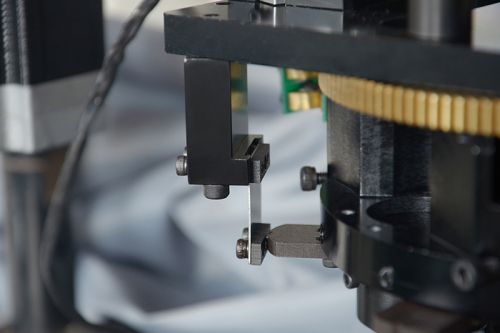

- The switching of location adopts mechanical and electronic for precise positioning, which prevents from damaging the indenters caused by mismatch between indenter and test force.

Request a quote

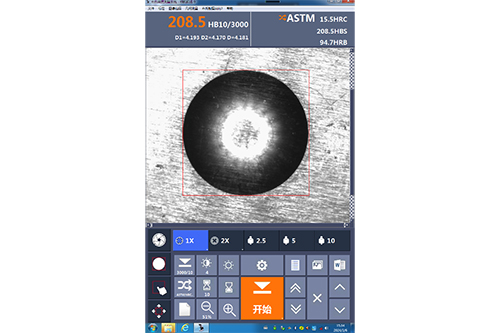

- The rigorous optical structure and high magnification make the observed indentation very clear.

- Objective and indenter are automatically shifted based on the selected scale, and then the hardness tester will perform the measuring and observing.

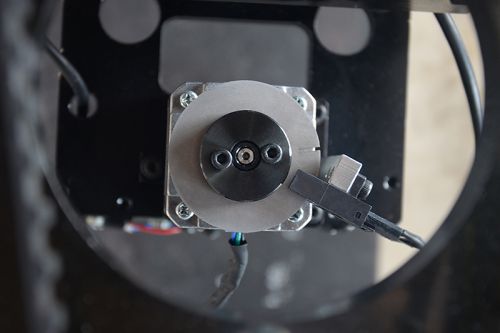

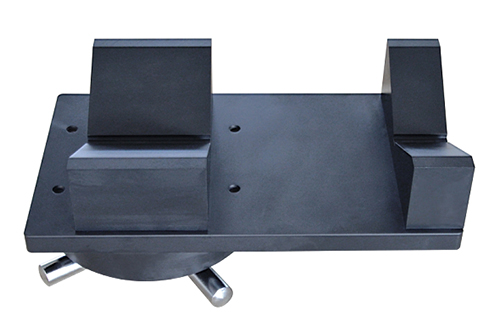

- The automatic lifting table uses precision structure for high stability and it will automatically rises when the test starts, and then return to the focusing position for measuring after the test force is loaded.

- This hardness tester adopts integrated design of tester and computer, using Windows 7 operating system.

- Built-in CCD camera and touch screen allows for preseting of dwell time of test force, adjusting the intensity of light source, displaying of indentation length, hardness vaule, test range, test number, etc.

- The software features function of calibration, allowing manual fine tuning and setting up of top and bottom limit for alarming, which ensures the measuring precision.

- Conversion scales allows selection for various scales of hardness.

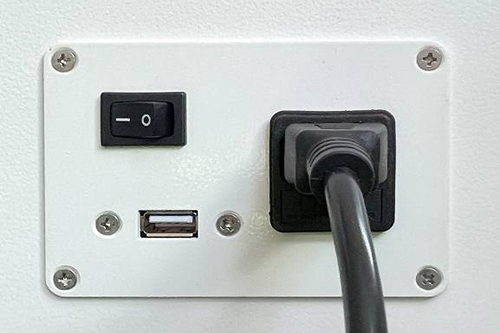

- USB port, VGA interface and LAN interface are available for connecting to the internet and other devices for more optional functions.

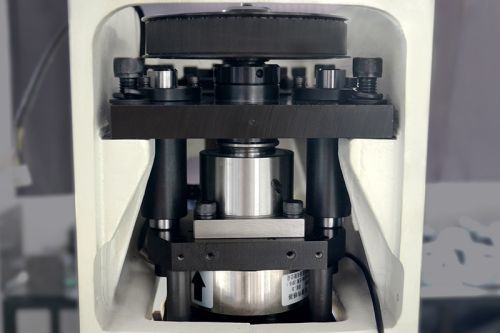

- The main body is made of cast iron, achieving 99% rigidity and minimizing deformation. The tester’s housing has undergone a natural aging process for over six months, ensuring stable physical properties.

- Features a high-precision gravity sensing system combined with a gap-free ball screw, allowing for accurate 1:1 control of the test force. With a 0.03-grade force sensor, it ensures precise and consistent loading every time.

- The screw rod, equipped with imported NSK bearings from Japan and a ball screw, undergoes heat treatment to reach a hardness of 35-40HRC. This enhances the stability of test data at different heights.

Applications

XHBT-3000Z II Hardness tester is suitable for measuring cast iron, steel, nonferrous metals, soft alloys and non-metal materials like rigid plastics, bakelite, etc.

Technical Data

- Test force: 62.5kgf, 100kgf, 125kgf, 187.5kgf, 250kgf, 500kgf, 750kgf, 1000kgf, 1500kgf, 3000kgf

612.9N, 980.7N, 1226N, 1839N, 2452N, 4903N, 7355N, 9807N, 14710N, 29420N - Max. sample height: 290mm

- Test range: 3.18~653HBW

- Loading method: automatic (loading/dwell/unloading)

- Hardness reaaading: 12 inch touch screen, automatic measuring

- Micro computer: CPU: Intel I5, memory: 8G, SSD: 128G

- CCD pixel: 3 million

- Conversion scale: HV, HK, HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRKW, HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW, HS, HBS, HBW

- Data optput: 3×USB, 1×VGA, 1×LAN

- Turret: automatic recognization and shafting (three indenters, two objectives)

- Objective: 1×, 2×

- Effective field of view: 1×: 6mm, 2×: 3mm

- Min. measuring unit: 1×:4.6μm,2×:2.3μm

- Dwell time: 0~99s

- Throat depth: 150mm

- Eecute standard: ISO 6506, ASTM E10, JIS Z2243, GB/T 231.2

Optional Accessories

Get in Touch

SCTMC is a reliable manufacturer of metallographic sample preparation equipment and hardness testers. Our factory is equipped with more than 50 sets of CNC lathes, Mazak machine tool from Japan, German Zeiss CMM and other advanced machines for manufacturing and inspecting, enabling us to provide high quality equipment which is highly praised by 150+ dealers and 1500+ clients across countries at home and abroad. Our machines have found wide applications in the automotive industry, metallurgy, R&D, universities and testing labs for material preparation, testing and analysis of all types of materials, such as metals, ceramics, rocks and minerals, organic materials and plastics. Our products deliver the highest quality, innovation, accuracy, efficiency, operator safety and repeatability you need.