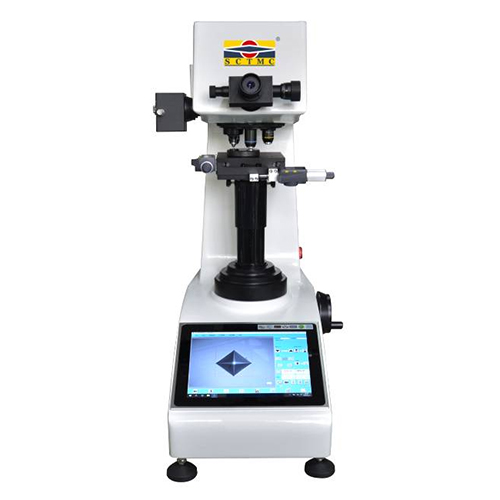

XHVT-10Z30Z50Z Vickers Hardness Tester with CCD Camera

Hardness Testing Machine

- Test force range: 0.2kgf (1.96N) ~ 50kgf (490N)

- Integrated design of hardness tester and computer, with Windows 7 system, this hardness tester can be connected to external displayer and printer.

- Touch screen comes with convenient operation, clear and intitute display.

- The lifting screw adopts worm and gear structure for smooth transmission.

- XHVT-10Z30Z50Z Vickers hardness tester adopts 3 objectives for measuring, and features automatic regonization and shafting between objective and indenter.

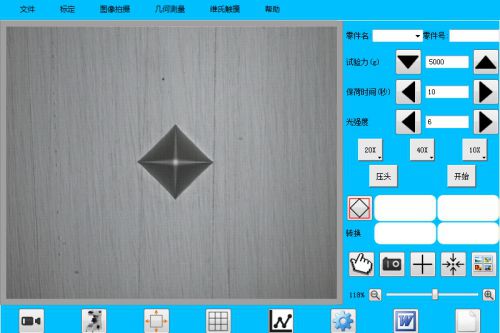

- Built-in CCD camera offers clear indentation image and automatic hardness measuring.

Request a quote

- The hardness tester features high measuring precision and stable performance, elinimating manual error.

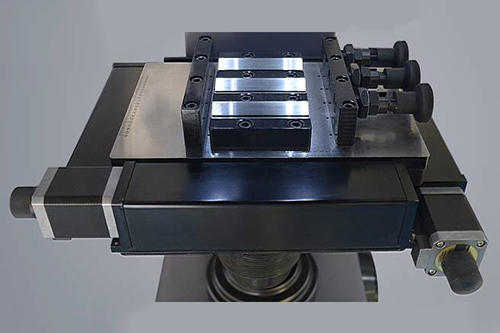

- Digital test table offers accurate positioning and measuring.

- Automatic loading/dwell/unloading of test force

- Supports scale conversion.

- The main body is constructed from cast aluminum, achieving 99% rigidity and minimizing deformation

- Made from a special material and heat-treated to achieve a hardness of 35-40HRC, the screw rod is highly wear-resistant. The worm gear structure ensures smoother elevation

- The tester automatically records measurement data and can generate hardness-depth curves, which can be saved as Word or Excel reports

- Equipped with USB, VGA, and network interfaces, allowing users to connect to networks and other devices, providing more functionality and options

Applications

XHVT-10Z30Z50Z Vickers hardness tester is suitable for the hardness testing of ferrous metals, non-ferrous metals, IC thin sections, coatings, ply-metals, and glass, ceramics, agate, precious stones, thin plastics, as well as the depth and trapezium of the carbonized layers and quench hardened layers.

Technical Data

- Test force: XHVT-10Z:0.2kgf (1.96N), 0.3kgf (2.94N), 0.5kgf (4.90N), 1kgf (9.80N), 2kgf (19.6N), 2.5kgf (24.5N), 3kgf (29.4N), 5kgf (49N), 10kgf (98N)

- XHVT-30Z:0.3kgf (2.94N), 0.5kgf (4.90N), 1kgf (9.80N), 2kgf (19.6N), 2.5kgf (24.5N), 3kgf (29.4N), 5kgf (49N), 10kgf (98N), 20kgf (196N), 30kgf (294N)

- XHVT-50Z:0.5kgf (), 1kgf (9.80N), 2kgf (19.6N), 2.5kgf (24.5N), 3kgf (29.4N), 5kgf (49N), 10kgf (98N), 20kgf (196N), 30kgf (294N), 50kgf (490N)

- Max. sample height: 170mm

- Test mode: HV/HK

- Test range: 1HV~2967HV

- Loading method: automatic (loading/dwell/unloading)

- Turret: automatic shafting of indenter and objective

- Micro computer: CPU: Intel I5, memory: 4G, SSD: 240G

- CCD pixel: 1.3 million

- Conversion scale: HV, HK, HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRKW, HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW, HS, HBW

- Hardness reading: automatic reading, touch screen displays the indentation

- Data output: Word or Excel report for curve graph

- Objective: 10×, 20×, 40×

- Effective field of view: 10×: 680μm, 20×: 340μm, 40×: 170μm

- Min. measuring unit: 10×: 0.1μm, 20×: 0.05μm, 40×: 0.025μm

- Dwell time: 0~60s

- Light source: Halogen lamp

- X-Y table: Size: 120×120mm, travel: 25×25mm, resolution: 0.001mm

- Throat depth: 130mm

- Execute standard: ISO 6507,ASTM E92,JIS Z2244,GB/T 4340.2

- Dimension: 560×335×675mm

- Net Weight: 48kg

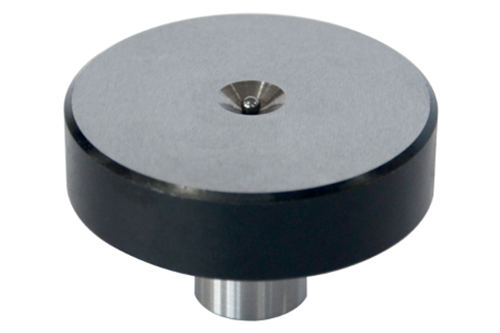

Optional Accessories

Get in Touch

SCTMC is a reliable manufacturer of metallographic sample preparation equipment and hardness testers. Our factory is equipped with more than 50 sets of CNC lathes, Mazak machine tool from Japan, German Zeiss CMM and other advanced machines for manufacturing and inspecting, enabling us to provide high quality equipment which is highly praised by 150+ dealers and 1500+ clients across countries at home and abroad. Our machines have found wide applications in the automotive industry, metallurgy, R&D, universities and testing labs for material preparation, testing and analysis of all types of materials, such as metals, ceramics, rocks and minerals, organic materials and plastics. Our products deliver the highest quality, innovation, accuracy, efficiency, operator safety and repeatability you need.